Nanowear ®

Nanowear® is applied to components used in the oil and gas industry to reduce corrosion and increase wear resistance. It also helps resist erosion and abrasion while increasing the fatigue strength of the base material. Top coats can also be applied to reduce the coefficient of friction.

Nanowear® is applied to components used in the oil and gas industry to reduce corrosion and increase wear resistance. It also helps resist erosion and abrasion while increasing the fatigue strength of the base material. Top coats can also be applied to reduce the coefficient of friction.

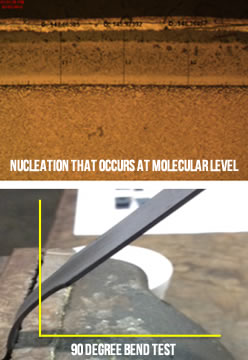

Woodworth Incorporated’s Nanowear ® technology is a thermal chemical diffusion process. It is important to note that it is not a coating. Nanowear ® is a nanotechnology and alters the base material’s structure at the molecular level.

- Creates a hard outside layer that can exceed Rockwell C 70 but remain ductile.

- Creates a continuous layer of nitrogen at the surface to significantly reduce corrosion

- Diffusion zone, typically 10 (ten) Rockwell points greater than the core hardness.

- Nanowear ® is a “green” technology.

Components

- Artificial Lift - ESP

- Fluid End Valves and Seats

- Offshore Housings

- Centralizers

- Blowout Preventer pistons, shafts, casings

- Drilling Rig Bases

- Pipelines

- Wellhead Components

- Drilling Rig Housings

- Seawall Pilings